Downhole Motors

Downhole Motors

Downhole motor is a kind of downhole dynamic drilling tool drove by the hydraulic power of drilling mud. Rotor drive the shaft and bit rotating to achieve drilling aim . Driven power fluid as oil-based mud, emulsion mud and clay mud. It’s adaptable and flexible ,can be applied to horizontal wells and c...

- E-mail: Sales@machtec.cn

- Phone: +86 22 60978800

Downhole motor is a kind of downhole dynamic drilling tool drove by the hydraulic power of drilling mud. Rotor drive the shaft and bit rotating to achieve drilling aim . Driven power fluid as oil-based mud, emulsion mud and clay mud. It’s adaptable and flexible ,can be applied to horizontal wells and cluster wells drilling operators .MTC can supply the following downhole motors :

1. Bent Down-hole motor: The bent angle on the universal axis can fit curvature of kicking off ,Single – bent and double –bent are available , The curvature of kicking-off can achieve 1•/m and shorter length of whole .

2.Uniform thickness down-hole motor : The uniform wall thickness down-hole motor changes the shape of the stator shell to make the stator rubber thin and uniform in order to overcome the conventional technology of drill stator and effectively improve the working environment of down-hole motor

3. Saturated saltwater mud resistant down-hole motor :The special coating layer of rotor has stronger ability of corrosion and wear resistance ,enabling the down –hole motor to work for a long time in saturated saltwater mud .

4.High temperature down-hole motor :The resistant temperature of motor can achieve over 150℃ by the using of excellent resistant temperature rubber in the stator ,With the ability of resistant temperature rubber in the stator ,the requirement of the deep well ,up dell well and high temperature grads areas drilling can be satisfied .

5.Sealed transmission shaft down-hole motor :Converting the mud condition of thrust axletree and radial axletree,make the whole downhole motor life long .

By-Pass valve assembly

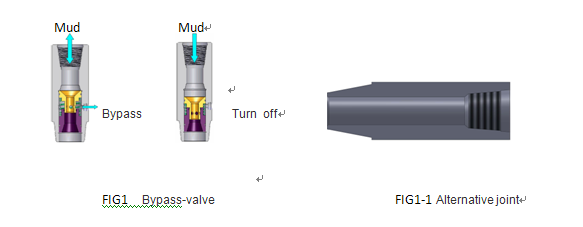

It has two positions of by-pass and close (Fig.1). It is in by-pass position during trip operation, circulates mud fluid in the drill string into the annular space by-passing the idle motor,so that no mud may spray out onto the platform during the trip operation. When mud flow rate and pressure reach the setting value, the valve stem moves down and closes the valve. Meanwhile, mud stream flows through the motor, and converts the pressure energy into mechanical energy. As mud flow rate is too low, or mud pump stops, and as the created pressure is not enough to overcome spring force and static friction force, the spring presses the stem upward, and by-pass valve is in open position. Normal situation ,deep-hole ,highly-deviated well, horizontal well usually use alternative joint (FIG 1-1)

Motor assembly

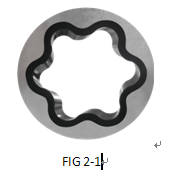

It consists of stator and rotor. Stator is made by squeezing rubber sleeve on the inner wall of steel tube. Rubber sleeve inner hole forms spiral structure with a certain geometric parameter. Rotor is a screw rod with chrome-plated layer.

MTC motors has following advantages :

1.Stator and rotator are made of 42CrMo material ,whose rigidity can reach up to HB285-341 & HB260-300 , mechanical property of material got very big enhancement .

2.Enable optimize and design the line according to the requirement of customers and usage , significantly improving the efficiency of whole tool

3.Full range of motors used for different drilling sites is available.According to working temperature :

a) Normal temperature stator : Rated temperature is 95℃,highest temperature is 120℃;

b) High temperature stator : Rated temperature is 105℃,highest temperature is 150℃

c) Ultra high temperature of the stator : Rated temperature is 165℃,highest temperature is 180℃

By mud type :

a) Water-base mud

b) Oil-base mud

c) High saturated salt mud

To increase hydraulic horsepower and upward speed of mud stream, rotor is manufactured into hollow rotor with nozzles.

Interference size of rotor and stator can as different service condition of customers to recommend different matching size ,which can enhance the service life of motors and working efficiency

MTC uniform wall thickness down-hole motor has the following advantages :

a) Single stage bear high pressure ,improved system efficiency ;

b) Fine thermal efficiency ,significantly enhanced the service life of stator

c) Even rubber swelling ,more stability of stator ;

d) Improved the binding area and adhesive strength between rubber and metal , used in a wider range, more optimized structure, and lighter quality;

MTC can provide rotors within different medium according to working condition ;

a) Conventional rotor : chrome-faced ,suiting for water base fluids and oil-base fluids ;

b) Tungsten carbide rotor : surface spraying tungsten carbide, suiting for saturated saltwater mud

c) Ceramic rotor : surface spraying ceramic, suiting for saturated saltwater mud

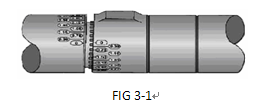

Universal shaft assembly

The function of cardan shaft is to convert planetary motion into fixed constant rotation of drive shaft, to transmit torque speed from motor on the drive shaft, and to the bit. Cardan shaft mostly use flat shaft, but some are flexible shafts. (Figure 3)

After using tools ,operators should tear down and check the cardan shaft quickly, who should replace the quick-wear part if the degree of abrasion beyond the repair standards ,otherwise ,the tools will not work normal because of overuse cardan shaft

The maximum angle of adjustable cardan shaft can up to 0-4°,also can customized for more adjustable range shell to meet the requirement of working condition . (Figure 3-1)

Drive shaft assembly

Drive shaft is to transmit motor rotary dynamic force onto the bit , meanwhile bearing axial and radial load from drilling weight .MTK can manufacture two types drive shaft like following :

a) 7.0Mpa bit nozzle pressure ,using hard alloy radial bearing and drive shaft assembly with thrust bearings ;

b) 14.0Mpa bit nozzle pressure, using hard alloy radial bearing and PDC cutter flat thrust bearing .It is longer lasting lift and higher bearing capacity .

MTC drive shaft undergoing machine – shaping after forging consist of 40CrNiMoA high performance alloy steel material .

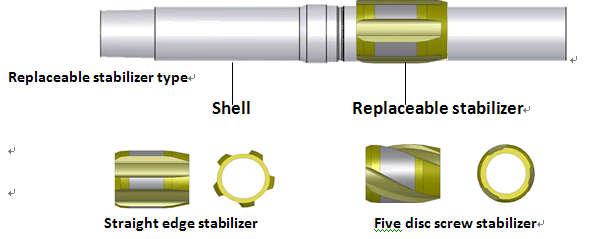

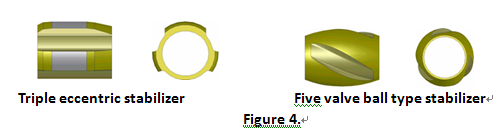

To meet drilling needs ,MTC drive shaft assembly equipped sorts of stabilizers, which include fixed type and replaceable type for choosing according to drilling process .( Figure 4.)

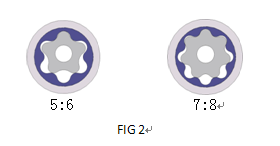

Model | Outer Diameter (mm) | Lobe | Stage | Length of drilling rig length | Effective length of stator | Max Diameter of Drive Shaft Assembly (mm) | Lower Boom Length (mm) | Up Thread | Down Thread |

5LZ43×7.0 M-4 | 43 | 5:6 | 4 | 1707 | 820 | 43 | \ | 1AMMT | 1AMMT |

5LZ45×7.0 M-3 | 45 | 5:6 | 3 | 1927 | 1040 | 45 | \ | 1AMMT | 1AMMT |

5LZ54×7.0 M-3 | 54 | 5:6 | 3 | 2119 | 1130 | 54 | \ | 1REG | 1REG |

7LZ54×7.0 M-4 | 54 | 7:8 | 4 | 2699 | 1710 | 54 | \ | 1REG | 1REG |

5LZ60×7.0 M-3 | 60 | 5:6 | 3 | 3745 | 1850 | 60 | \ | 1REG | 1REG |

5LZ73×7.0 M-7 | 73 | 5:6 | 7 | 4717 | 2850 | 73 | 813 | 2 3/8REG (3-66) | 2 3/8REG (3-66) |

5LZ79×7.0 M-4 | 79 | 5:6 | 4 | 4355 | 2450 | 79 | 779 | 2 3/8REG (3-66) | 2 3/8REG (3-66) |

5LZ79×7.0 M-5 | 79 | 5:6 | 5 | 4855 | 3000 | 79 | 779 | 2 3/8REG (3-66) | 2 3/8REG (3-66) |

7LZ79×7.0 M-4 | 79 | 7:8 | 4 | 3525 | 1650 | 79 | 779 | 2 3/8REG (3-66) | 2 3/8REG (3-66) |

7LZ79×7.0 M-4 | 79 | 7:8 | 4 | 3525 | 1650 | 79 | 779 | 2 3/8REG (3-66) | 2 3/8REG (3-66) |

5LZ89×7.0 M-4 | 89 | 5:6 | 4 | 4759 | 2450 | 89 | 1103 | 2 3/8REG (3-66) | 2 3/8REG (3-66) |

4LZ95×7.0 M-5 | 95 | 4:5 | 5 | 5619 | 3050 | 95 | 1062 | NC-31 (3-86) | 2 7/8REG (3-76) |

5LZ95×7.0 M-3 | 95 | 5:6 | 3 | 4419 | 1850 | 95 | 1062 | NC-31 (3-86) | 2 7/8REG (3-76) |

5LZ95×7.0 M-5 | 95 | 5:6 | 5 | 5619 | 3050 | 95 | 1062 | NC-31 (3-86) | 2 7/8REG (3-76) |

5LZ95×7.0 M-7 | 95 | 5:6 | 7 | 5979 | 3410 | 95 | 1062 | NC-31 (3-86) | 2 7/8REG (3-76) |

7LZ95×7.0 M-3 | 95 | 7:8 | 3 | 4419 | 1850 | 95 | 1062 | NC-31 (3-86) | 2 7/8REG (3-76) |

7LZ95×7.0 M-10.1 | 95 | 7:8 | 10.1 | 7869 | 5300 | 95 | 1062 | NC-31 (3-86) | 2 7/8REG (3-76) |

7LZ95×7.0 M-6.7 | 95 | 7:8 | 6.7 | 6749 | 4180 | 95 | 1062 | NC-31 (3-86) | 2 7/8REG (3-76) |

9LZ95×7.0 M-4 | 95 | 9:10 | 4 | 5019 | 2450 | 95 | 1062 | NC-31 (3-86) | 2 7/8REG (3-76) |

5LZ105×7.0 M-4 | 105 | 5:6 | 4 | 4898 | 2450 | 105 | 1138 | 3 1/2REG (3-88) | 2 7/8REG (3-76) |

5LZ105×7.0 M-10.1 | 105 | 5:6 | 10.1 | 7768 | 5320 | 105 | 1138 | 3 1/2REG (3-88) | 2 7/8REG (3-76) |

7LZ105×7.0 M-6 | 105 | 7:8 | 6 | 6678 | 4230 | 105 | 1138 | 3 1/2REG (3-88) | 2 7/8REG (3-76) |

9LZ105×7.0 M-6 | 105 | 9:10 | 6 | 6458 | 4010 | 105 | 1138 | 3 1/2REG (3-88) | 2 7/8REG (3-76) |

7LZ108×7.0 M-6 | 108 | 7:8 | 6 | 6818 | 4370 | 108 | 1138 | 3 1/2REG (3-88) | 2 7/8REG (3-76) |

5LZ120×7.0 M-5 | 120 | 5:6 | 5 | 7192 | 4540 | 120 | 1223 | NC-38(З-102) | 3 1/2REG (3-88) |

5LZ120×7.0 M-6 | 120 | 5:6 | 6 | 7892 | 5240 | 120 | 1223 | NC-38(З-102) | 3 1/2REG (3-88) |

7LZ120×7.0 M-4 | 120 | 7:8 | 4 | 6282 | 3630 | 120 | 1223 | NC-38(З-102) | 3 1/2REG (3-88) |

7LZ120×7.0 M-6.5 | 120 | 7:8 | 6.5 | 8522 | 5870 | 120 | 1223 | NC-38(З-102) | 3 1/2REG (3-88) |

7LZ120×7.0 M-7 | 120 | 7:8 | 7 | 7092 | 4420 | 120 | 1223 | NC-38(З-102) | 3 1/2REG (3-88) |

7LZ120×7.0 M-8 | 120 | 7:8 | 8 | 7692 | 5040 | 120 | 1223 | NC-38(З-102) | 3 1/2REG (3-88) |

4LZ127×7.0 M-6 | 127 | 4:5 | 6 | 7052 | 4400 | 127 | 1223 | NC-38(З-102) | 3 1/2REG (3-88) |

4LZ127×7.0 M-5 | 127 | 4:5 | 5 | 6332 | 3680 | 127 | 1223 | NC-38(З-102) | 3 1/2REG (3-88) |

5LZ127×7.0 M-5 | 127 | 5:6 | 5 | 7022 | 4370 | 127 | 1223 | NC-38(З-102) | 3 1/2REG (3-88) |

7LZ127×7.0 M-4 | 127 | 7:8 | 4 | 6282 | 3630 | 127 | 1223 | NC-38(З-102) | 3 1/2REG (3-88) |

7LZ127×7.0 M-7 | 127 | 7:8 | 7 | 7092 | 4420 | 127 | 1223 | NC-38(З-102) | 3 1/2REG (3-88) |

7LZ135×7.0 M-5 | 135 | 7:8 | 5 | 7775 | 4450 | 135 | 1280 | NC-38(З-102) | 3 1/2REG (3-88) |

7LZ140×7.0 M-5 | 140 | 7:8 | 5 | 7425 | 4100 | 140 | 1495 | NC-50(З-133) | 4 1/2REG (3-117) |

5LZ159×7.0 M-5 | 159 | 5:6 | 5 | 8067 | 4250 | 159 | 1939 | NC-50(З-133) | 4 1/2REG (3-117) |

7LZ159×7.0 M-3 | 159 | 7:8 | 3 | 7227 | 3410 | 159 | 1939 | NC-50(З-133) | 4 1/2REG (3-117) |

4LZ165×7.0 M-7 | 165 | 4:5 | 7 | 9257 | 5440 | 165 | 1872 | NC-50(З-133) | 4 1/2REG (3-117) |

5LZ165×7.0 M-4 | 165 | 5:6 | 4 | 7227 | 3410 | 165 | 1872 | NC-50(З-133) | 4 1/2REG (3-117) |

5LZ165×7.0 M-5 | 165 | 5:6 | 5 | 8067 | 4250 | 165 | 1872 | NC-50(З-133) | 4 1/2REG (3-117) |

5LZ165×7.0 M-6 | 165 | 5:6 | 6 | 8907 | 5090 | 165 | 1872 | NC-50(З-133) | 4 1/2REG (3-117) |

7LZ165×7.0 M-5 | 165 | 7:8 | 5 | 9617 | 5800 | 165 | 1872 | NC-50(З-133) | 4 1/2REG (3-117) |

4LZ172×7.0 M-7 | 172 | 4:5 | 7 | 9257 | 5440 | 172 | 1867 | 5 1/2FH (З-147) | 4 1/2REG (3-117) |

5LZ172×7.0 M-4 | 172 | 5:6 | 4 | 7227 | 3410 | 172 | 1867 | 5 1/2FH (З-147) | 4 1/2REG (3-117) |

5LZ172×7.0 M-5 | 172 | 5:6 | 5 | 8067 | 4250 | 172 | 1867 | 5 1/2FH (З-147) | 4 1/2REG (3-117) |

5LZ172×7.0 M-6 | 172 | 5:6 | 6 | 8907 | 5090 | 172 | 1867 | 5 1/2FH (З-147) | 4 1/2REG (3-117) |

6LZ172×7.0 M-6.5 | 172 | 6:7 | 6.5 | 8417 | 4600 | 172 | 1867 | 5 1/2FH (З-147) | 4 1/2REG (3-117) |

7LZ172×7.0 M-5 | 172 | 7:8 | 5 | 8437 | 4620 | 172 | 1867 | 5 1/2FH (З-147) | 4 1/2REG (3-117) |

7LZ172×7.0 M-5.5 | 172 | 7:8 | 5.5 | 8897 | 5080 | 172 | 1867 | 5 1/2FH (З-147) | 4 1/2REG (3-117) |

7LZ172×7.0 M-6 | 172 | 7:8 | 6 | 9347 | 5530 | 172 | 1867 | 5 1/2FH (З-147) | 4 1/2REG (3-117) |

7LZ172×7.0 M-5.7 | 172 | 7:8 | 5.7 | 10027 | 6210 | 172 | 1867 | 5 1/2FH (З-147) | 4 1/2REG (3-117) |

7LZ172×7.0 M-7.5 | 172 | 7:8 | 7.5 | 10167 | 6350 | 172 | 1867 | 5 1/2FH (З-147) | 4 1/2REG (3-117) |

3LZ178×7.0 M-6 | 178 | 3:4 | 6 | 8832 | 5090 | 178 | 1923 | 5 1/2FH (З-147) | 4 1/2REG (3-117) |

4LZ178×7.0 M-7 | 178 | 4:5 | 7 | 9172 | 5440 | 178 | 1923 | 5 1/2FH (З-147) | 4 1/2REG (3-117) |

5LZ178×7.0 M-4 | 178 | 5:6 | 4 | 7152 | 3410 | 178 | 1923 | 5 1/2FH (З-147) | 4 1/2REG (3-117) |

5LZ178×7.0 M-5 | 178 | 5:6 | 5 | 7992 | 4250 | 178 | 1923 | 5 1/2FH (З-147) | 4 1/2REG (3-117) |

5LZ178×7.0 M-6 | 178 | 5:6 | 6 | 8832 | 5090 | 178 | 1923 | 5 1/2FH (З-147) | 4 1/2REG (3-117) |

5LZ178×7.0 M-7 | 178 | 5:6 | 7 | 10292 | 6560 | 178 | 1923 | 5 1/2FH (З-147) | 4 1/2REG (3-117) |

6LZ178×7.0 M-6.5 | 178 | 6:7 | 6.5 | 8962 | 5230 | 178 | 1923 | 5 1/2FH (З-147) | 4 1/2REG (3-117) |

7LZ178×7.0 M-5 | 178 | 7:8 | 5 | 8362 | 4620 | 178 | 1923 | 5 1/2FH (З-147) | 4 1/2REG (3-117) |

7LZ178×7.0 M-5.5 | 178 | 7:8 | 5.5 | 8897 | 5080 | 178 | 1867 | 5 1/2FH (З-147) | 4 1/2REG (3-117) |

7LZ178×7.0 M-5.7 | 178 | 7:8 | 5.7 | 9952 | 6210 | 178 | 1923 | 5 1/2FH (З-147) | 4 1/2REG (3-117) |

7LZ178×7.0 M-6 B | 178 | 7:8 | 6 | 9262 | 5530 | 178 | 1923 | 5 1/2FH (З-147) | 4 1/2REG (3-117) |

7LZ178×7.0 M-6 I | 178 | 7:8 | 6 | 8932 | 5090 | 178 | 1923 | 5 1/2FH (З-147) | 4 1/2REG (3-117) |

7LZ178×7.0 M-6 | 178 | 7:8 | 6 | 8932 | 5200 | 178 | 1923 | 5 1/2FH (З-147) | 4 1/2REG (3-117) |

F7LZ178×7.0 M-6 | 178 | 7:8 | 6 | 8932 | 5200 | 178 | 1923 | 5 1/2FH (З-147) | 4 1/2REG (3-117) |

7LZ178×7.0 M-7 | 178 | 7:8 | 7 | 8992 | 5260 | 178 | 1923 | 5 1/2FH (З-147) | 4 1/2REG (3-117) |

7LZ178×7.0 M-7.5 | 178 | 7:8 | 7.5 | 10092 | 6350 | 178 | 1923 | 5 1/2FH (З-147) | 4 1/2REG (3-117) |

7LZ185×7.0 M-7 | 185 | 7:8 | 7 | 9672 | 5930 | 185 | 1923 | 5 1/2FH (З-147) | 6 5/8REG (З-152) |

3LZ197×7.0 M-7 | 197 | 3:4 | 7 | 10063 | 5930 | 197 | 2184 | 5 1/2FH (З-147) | 6 5/8REG (З-152) |

4LZ197×7.0 M-6 | 197 | 4:5 | 6 | 9223 | 5090 | 197 | 2184 | 5 1/2FH (З-147) | 6 5/8REG (З-152) |

5LZ197×7.0 M-4 | 197 | 5:6 | 4 | 7543 | 3410 | 197 | 2184 | 5 1/2FH (З-147) | 6 5/8REG (З-152) |

5LZ197×7.0 M-5 | 197 | 5:6 | 5 | 8383 | 4250 | 197 | 2184 | 5 1/2FH (З-147) | 6 5/8REG (З-152) |

5LZ197×7.0 M-6 | 197 | 5:6 | 6 | 9223 | 5090 | 197 | 2184 | 5 1/2FH (З-147) | 6 5/8REG (З-152) |

6LZ197×7.0 M-5 | 197 | 6:7 | 5 | 8383 | 4250 | 197 | 2184 | 5 1/2FH (З-147) | 6 5/8REG (З-152) |

6LZ197×7.0 M-6 | 197 | 6:7 | 6 | 9223 | 5090 | 197 | 2184 | 5 1/2FH (З-147) | 6 5/8REG (З-152) |

9LZ197×7.0 M-4 | 197 | 9:10 | 4 | 7543 | 3410 | 197 | 2184 | 5 1/2FH (З-147) | 6 5/8REG (З-152) |

7LZ197×7.0 M-5 | 197 | 7:8 | 5 | 8383 | 4250 | 197 | 2184 | 5 1/2FH (З-147) | 6 5/8REG (З-152) |

4LZ203×7.0 M-6 | 203 | 4:5 | 6 | 9397 | 5090 | 203 | 2192 | 5 1/2FH (З-147) | 6 5/8REG (З-152) |

5LZ203×7.0 M-5 | 203 | 5:6 | 5 | 8857 | 4550 | 203 | 2192 | 5 1/2FH (З-147) | 6 5/8REG (З-152) |

5LZ203×7.0 M-6 | 203 | 5:6 | 6 | 9757 | 5450 | 203 | 2192 | 5 1/2FH (З-147) | 6 5/8REG (З-152) |

7LZ203×7.0 M-5 | 203 | 7:8 | 5 | 8557 | 4250 | 203 | 2192 | 5 1/2FH (З-147) | 6 5/8REG (З-152) |

3LZ210×7.0 M-7 | 210 | 3:4 | 7 | 10364 | 5930 | 210 | 2243 | 6 5/8REG (З-152) | 6 5/8REG (З-152) |

7LZ210×7.0 M-5 | 210 | 7:8 | 5 | 8704 | 4250 | 210 | 2243 | 6 5/8REG (З-152) | 6 5/8REG (З-152) |

7LZ210×7.0 M-7 | 210 | 7:8 | 7 | 10104 | 5650 | 210 | 2243 | 6 5/8REG (З-152) | 6 5/8REG (З-152) |

5LZ210×7.0 M-5 | 210 | 5:6 | 7 | 10104 | 5650 | 210 | 2243 | 6 5/8REG (З-152) | 6 5/8REG (З-152) |

5LZ216×7.0 M-6 | 216 | 5:6 | 6 | 9544 | 5090 | 216 | 2243 | 6 5/8REG (З-152) | 6 5/8REG (З-152) |

7LZ216×7.0 M-5 | 216 | 7:8 | 5 | 8704 | 4250 | 216 | 2243 | 6 5/8REG (З-152) | 6 5/8REG (З-152) |

5LZ228×7.0 M-6 | 228 | 5:6 | 6 | 9544 | 5090 | 228 | 2243 | 6 5/8REG (З-152) | 6 5/8REG (З-152) |

3LZ244×7.0 M-4 | 244 | 3:4 | 4 | 10633 | 6000 | 244 | 2371 | 6 5/8REG (З-152) | 6 5/8REG (З-152) |

3LZ244×7.0 M-6 | 244 | 3:4 | 6 | 10783 | 6210 | 244 | 2371 | 6 5/8REG (З-152) | 6 5/8REG (З-152) |

F3LZ244×7.0 M-6 | 244 | 3:4 | 6 | 10783 | 6210 | 244 | 2371 | 6 5/8REG (З-152) | 6 5/8REG (З-152) |

5LZ244×7.0 M-4 | 244 | 5:6 | 4 | 8663 | 4080 | 244 | 2371 | 6 5/8REG (З-152) | 6 5/8REG (З-152) |

5LZ244×7.0 M-5 | 244 | 5:6 | 5 | 9673 | 5090 | 244 | 2371 | 6 5/8REG (З-152) | 6 5/8REG (З-152) |

5LZ244×7.0 M-6 | 244 | 5:6 | 6 | 10683 | 6100 | 244 | 2371 | 6 5/8REG (З-152), 6 5/8 FH (З-171) | 6 5/8REG (З-152) |

C5LZ244×7.0 M-4 | 244 | 5:6 | 4 | 9673 | 5090 | 244 | 2371 | 6 5/8REG (З-152) | 6 5/8REG (З-152) |

7LZ244×7.0 M-4 | 244 | 7:8 | 4 | 8663 | 4080 | 244 | 2371 | 6 5/8REG (З-152) | 6 5/8REG (З-152) |

C7LZ244×7.0 M-4 | 244 | 7:8 | 4 | 9693 | 5110 | 244 | 2371 | 6 5/8REG (З-152) | 6 5/8REG (З-152) |

7LZ244×7.0 M-5 | 244 | 7:8 | 5 | 10113 | 5530 | 244 | 2371 | 6 5/8REG (З-152) | 6 5/8REG (З-152) |

7LZ244×7.0 M-5.7 | 244 | 7:8 | 5.7 | 10383 | 5800 | 244 | 2371 | 6 5/8REG (З-152) | 6 5/8REG (З-152) |

3LZ286×7.0 M-4 | 286 | 3:4 | 4 | 10240 | 5170 | 286 | 2600 | 6 5/8REG (З-152) | 6 5/8REG (З-152) |

If you have any questions or support, please fill in the following information and we will reply to you as soon as possible!!